WFL/M Series Belt Weigh Feeder

Description:

WFL/M Weigh Feeder is used for continuous weighing, feeding and dosing of bulk and powder materials, and can also realize open-loop and closed loop flow control. It can be widely applied in building materials, chemicals, coal, ports, ceramics, food, fertilizer, and other industries.

Principle:

Principle:

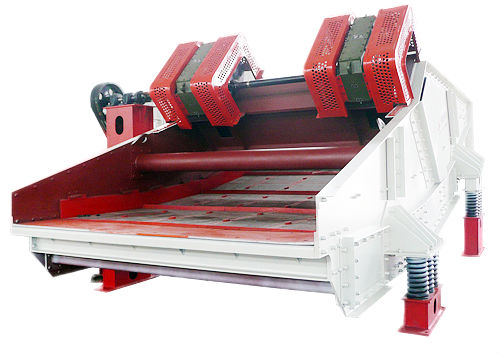

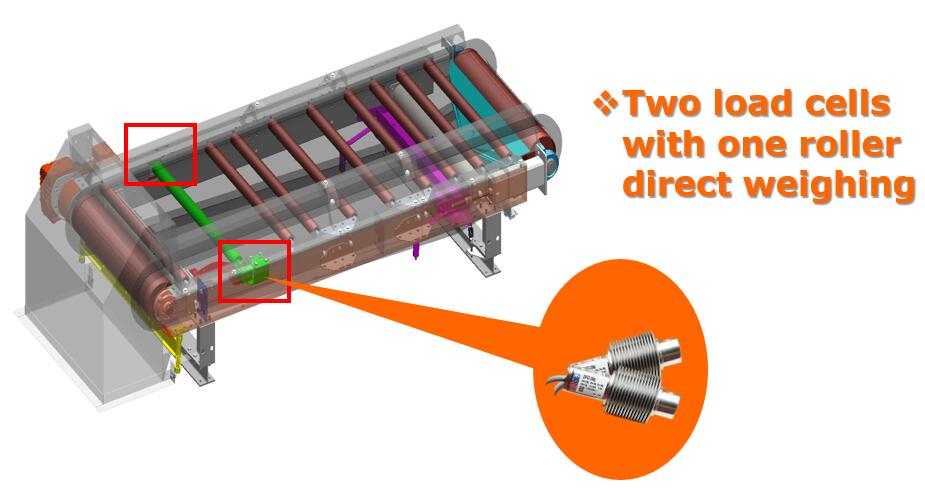

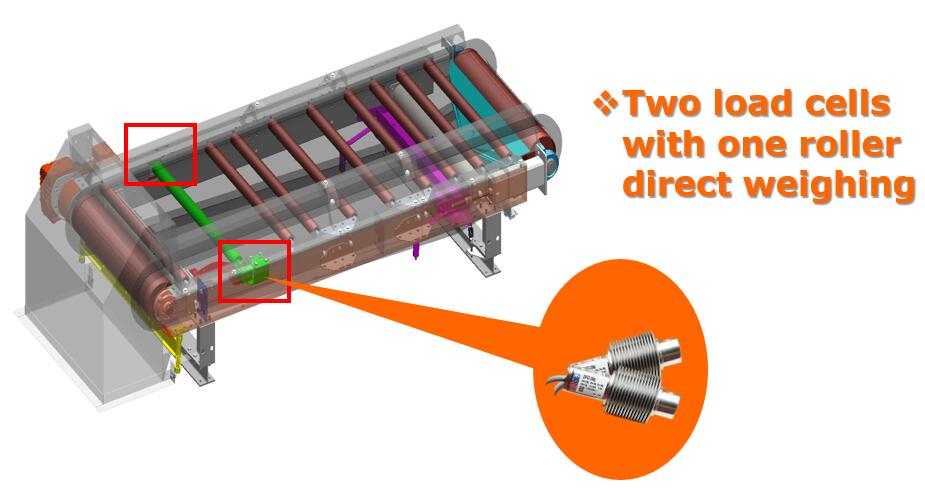

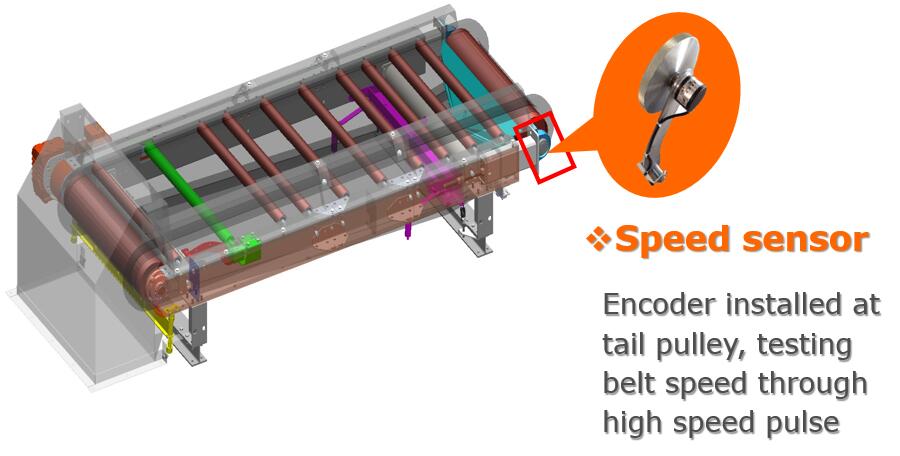

The electrical weighing device is installed under the belt, when the material works on the load cell which can generate a signal in proportion to the material weight and the signal is transmitted to the controller. At the same time, the speed sensor installed on the tail pulley detects the belt speed and generates a signal which is also transmitted to the controller. By multiplying the weight signal and the speed signal, the instantaneous flow rate and total accumulation can be calculated.

Main Features:

1. Reliable electrical weighing device: Unique structure and reliable weighing;

2. FB-DCS2000 control system, can be connected to DCS;

3. Unique deviation-resisting techniques ensure the belt operate well;

4. Belt of different width, thickness, environment suitability can be chosen according to specific process requirement;

5. Unique spillage proof device;

6. Unique belt tightening and aligning device;

7. Unique scraping device to protect belt and make the system operate well;

8. Sophisticated weighing system, no operation friction and with little maintenance.

9. Installation of load cell is treated specially to protect the load cell and ensure stable and reliable long-term operation;

10. High accuracy speed measuring device is the effective guarantee for system measurement;

11. Unique electrical automatic calibration, captive chai calibration, and weights-hoist calibration.

Specifications:

|

Items |

Parameters |

|

.Weighing accuracy |

±0.5% |

|

.Conveying capacity |

1~1000t/h |

|

.Belt width |

500~1800mm |

|

.Feeding distance |

≥1500mm |

|

.Speed range |

0.01~1.5m/s |

|

.Power range |

0.37~10kw |