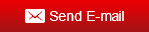

TWZ Series Horizontal Vibrating Centrifuge

Description:

This series product has sieve basket diameter of 850mm~1,500mm, and is mainly used for dewatering of lump clean coal, middlings and other similar materials, with 0.5mm~50mm feeding granule. It has advantages of small initial investment and floor area, low energy consumption, good dehydration effect, low coal crushing rate, long sieve basket life, convenient operation and maintenance and low noise, and sieve interval of 0.25, 0.3, 0.35, 0.5, etc.

Working principle:

The material get through the feed pipe with enamel and the sieve base, then enter into the bottom of the sieve basket. Pulled by the centrifugal base, material in the sieve basket clings to the screen surface. And then under the vibrating force, the material move uniformly to the big end of the sieve basket, finally the dewatering material is thrown out from all around the sieve basket, falling into the discharging port under the chasis, and then is discharged downward. As to the water in the material, pulled by the centrifugal force, getting through the material layer and screen cut, it is thrown out to all around the chasis and flows along the chasis wall to the water outlet.

Main features:

1. High handling capacity, fine dehydration effect

2. Less material grinding. The sieve basket is difficult to wear and has a long working life.

3. TWZ system applies inertia over resonance vibrating system, with stable and reliable amplitude and frequency.

4. TWZ vibrating system has advantages such as steady operation, low noise, simple structure, convenient maintenance and energy conservation etc.

Specificaiton:

|

Items |

Unit |

Model |

|

TWZ850 |

TWZ10A |

TWZ1150 |

TWZ1300 |

TWZ1400 |

TWZ1500 |

|

Feeding size |

mm |

≤50 |

0.5~13 |

0.5~50 |

0~50 |

≤50 |

0.5~50 |

|

Processing capacity |

t/h |

30~50 |

100 |

100~200 |

180~250 |

200~300 |

250~350 |

|

Moisture |

% |

5~9 |

|

Sieve basket diameter |

mm |

850 |

1000 |

1150 |

1300 |

1400 |

1500 |

|

Screen opening |

mm |

0.25,0.3,0.35,0.5 |

|

Basket angle |

° |

13 |

13 |

13 |

13 |

13 |

15 |

|

Double amplitude |

mm |

|

6 |

6 |

4~6 |

4~6 |

|

|

Basket rotational speed |

r/min |

450 |

380 |

350 |

310 |

290 |

270 |

|

Main motor power |

Kw |

15 |

22 |

37.5 |

45 |

55 |

75 |

|

Vibrating motor power |

Kw |

4 |

4 |

7.5 |

7.5 |

11 |

15 |

|

Oil pump motor power |

Kw |

0.37 |

0.37 |

0.37 |

0.55 |

0.55 |

1.1 |

|

Dimension |

L |

mm |

2060 |

2150 |

2800 |

2700 |

3100 |

3170 |

|

W |

mm |

1510 |

1875 |

1930 |

2260 |

3090 |

2975 |

|

H |

mm |

1625 |

1765 |

1930 |

2245 |

2295 |

2400 |

|

Weight |

Kg |

2500 |

2620 |

5527 |

6500 |

9200 |

10000 |