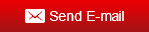

Sieve Plate for Vibrating Screen

We have different types of sieve plates for vibrating screens.

Polyurethane sieve plate is highly recommended.

Main application: Vibrating screens in coal washing plant, coking plant, mines, power plants, metallurgy, petroleum, petrochemical etc.

Performance and features:

1, wear-resisting performance prolongs the service life.

2, maintenance workload is small, the polyurethane sieve plate is not easy to damage, thus greatly reduce the amount of maintenance and maintenance shutdown loss.

3, moisture resistant performance is good, can work in the water medium conditions, and in the water, oil and other media, to reduce the friction coefficient of polyurethane and material, more conducive to screening, improve screening efficiency, and can avoid the adhesion of wet particles, at the same time because the friction coefficient decreased, wear reduced, service life to improve.

4, corrosion resistance, non flammable, non-toxic and tasteless.

5, because the mesh design is reasonable, the sieve plate manufacturing process is unique, does not limit the size of the particles block the mesh.

6, the vibration absorption performance is good, the noise elimination ability is strong, can reduce the noise, and can make the sieve material in the process of vibration is not easy to break.

7, because the two vibration characteristics of polyurethane, polyurethane sieve plate has self-cleaning effect, so the screening efficiency is high.

8, energy saving, polyurethane small proportion, than the same size steel sieve weight is much lighter, so as to reduce the machine load, saving power consumption, and prolong the life time of the screen machine.