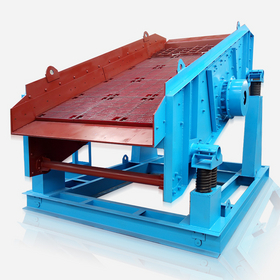

YA/YK Series Circular Vibrating Screen

Capacity: 70-1400t/h

Feeding Granularity: <400mm

Description:

1. The trajectory of YA circular vibrating screen is round, which uses an ordinary motor to drive the exciter, so that the screen body along the direction of exciting force for periodic reciprocating vibration. Then the material on the screen surface is doing continuous circular motion, so as to achieve the purpose of screening.

2. YA circular vibrating screen is composed of vibration source, sieve body, sieve mesh, damping device and bottom bracket. Screen machine side plate made of high quality steel, side panels and beams, exciter base with high strength bolts or ring groove rivet connection, sturdy and durable.

3. Adopt eccentric shaft plus eccentric block exciter, high-performance gear transmission system, low stress damping spring, Super heavy duty large clearance bearing, thin oil lubrication and other advanced technology, has the advantages of high sieve frame structure strength and reasonable mechanical structure.

4. Exciter is installed on the screen box, and by the motor through v-belt drive, generate centrifugal force, forced sieve box vibrating.

Working principle and structure characteristics:

YA series circular vibrating screen is using motor drive vibrator, the screen body of periodic vibration exciting force along the direction of the material, a continuous circular motion on the screen, so as to achieve the purpose of screening.

YA circular vibrating screen consists of vibration source, screen, screen body, a damping device and a bottom support plate, screen machine is made of high quality steel plate with side plates and beams, the exciter base with high strength bolts or ring groove rivet connection, reasonable structure, sturdy and durable.

Features:

1. Screen box vibration is strong, reducing the phenomenon of material blocking the sieve hole, so that the shaker has a higher screening efficiency and productivity.

2. Simple structure, easy to replace sieve mesh.

3. Screening per ton of material consumed by less energy, in line with energy-saving requirements.

4. Strong exciting force, low noise, large capacity, is the company's environmental protection products.

Specifications:

|

Model |

Mesh |

Feed size (mm) |

Capacity (t/h) |

Frequency (Hz) |

Motor |

|

layer |

Area (m2) |

Inclination agle(°) |

Opening (mm) |

material |

model |

Power (kw) |

|

2YA1230 |

2 |

3.7 |

20 |

6-50 |

②③ |

≤200 |

80-245 |

14.08 |

Y160M-4 |

11 |

|

YA1236 |

1 |

4.3 |

20 |

6-50 |

②③ |

≤200 |

80-245 |

14.08 |

Y160M-4 |

11 |

|

2YA1236 |

2 |

4.3 |

20 |

6-50 |

②③ |

≤200 |

80-245 |

14.08 |

Y160M-4 |

11 |

|

YA1530 |

1 |

4.5 |

20 |

6-50 |

②③ |

≤200 |

80-245 |

14.08 |

Y160M-4 |

11 |

|

2YA1530 |

2 |

4.3 |

20 |

6-50 |

②③ |

≤200 |

80-245 |

14.08 |

Y160M-4 |

15 |

|

YA1536 |

1 |

5.4 |

20 |

6-50 |

②③ |

≤200 |

95-350 |

14.08 |

Y160M-4 |

11 |

|

2YA1536 |

2 |

5.4 |

20 |

6-50 |

②③ |

≤200 |

95-350 |

14.08 |

Y160L-4 |

15 |

|

YAH1536 |

1 |

5.4 |

20 |

30-150 |

①③ |

≤400 |

240-660 |

12.58 |

Y160L-4 |

15 |

|

2YAH1536 |

2 |

5.4 |

20 |

30-1506-50 |

first layer①③

second layer②③ |

≤400 |

240-660 |

12.58 |

Y160L-4 |

15 |

|

YA1542 |

1 |

6.3 |

20 |

6-50 |

②③ |

≤200 |

110-360 |

14.08 |

Y160M-4 |

11 |

|

2YA1542 |

2 |

6.3 |

20 |

6-50 |

②③ |

≤200 |

110-360 |

14.08 |

Y160L-4 |

15 |

|

YA1548 |

1 |

7.2 |

20 |

6-50 |

②③ |

≤200 |

125-420 |

14.08 |

Y160L-4 |

15 |

|

2YA1548 |

2 |

7.2 |

20 |

6-50 |

②③ |

≤200 |

125-420 |

14.08 |

Y160L-4 |

15 |

|

YAH1548 |

1 |

7.2 |

20 |

30-150 |

①③ |

≤400 |

320-780 |

12.58 |

Y160L-4 |

15 |

|

2YAH1548 |

2 |

7.2 |

20 |

30-1506-50 |

first layer①③

second layer②③ |

≤400 |

320-780 |

12.58 |

Y160L-4 |

15 |

|

2YAH1556 |

2 |

8.23 |

20 |

30-1506-50 |

first layer①③

second layer②③ |

≤400 |

320-780 |

12.58 |

Y160L-4 |

15 |

|

2YA1645 |

2 |

7.3 |

20 |

30-1506-50 |

first layer①③

second layer②③ |

≤200 |

125-400 |

14.08 |

Y160L-4 |

15 |

|

YA1836 |

1 |

6.5 |

20 |

6-50 |

②③ |

≤200 |

130-370 |

14.08 |

Y160M-4 |

11 |

|

2YA1836 |

2 |

6.5 |

20 |

6-50 |

②③ |

≤200 |

130-370 |

14.08 |

Y160L-4 |

15 |

|

YHA1836 |

1 |

6.5 |

20 |

30-150 |

①③ |

≤400 |

290-800 |

12.58 |

Y160M-4 |

11 |

Remarks: ①Steel plate punched hole ② Steel wire woven ③ Polyurethane rectangular hole