Conveyor Belt Tear Detector Longitudinal Anti-crack Switch

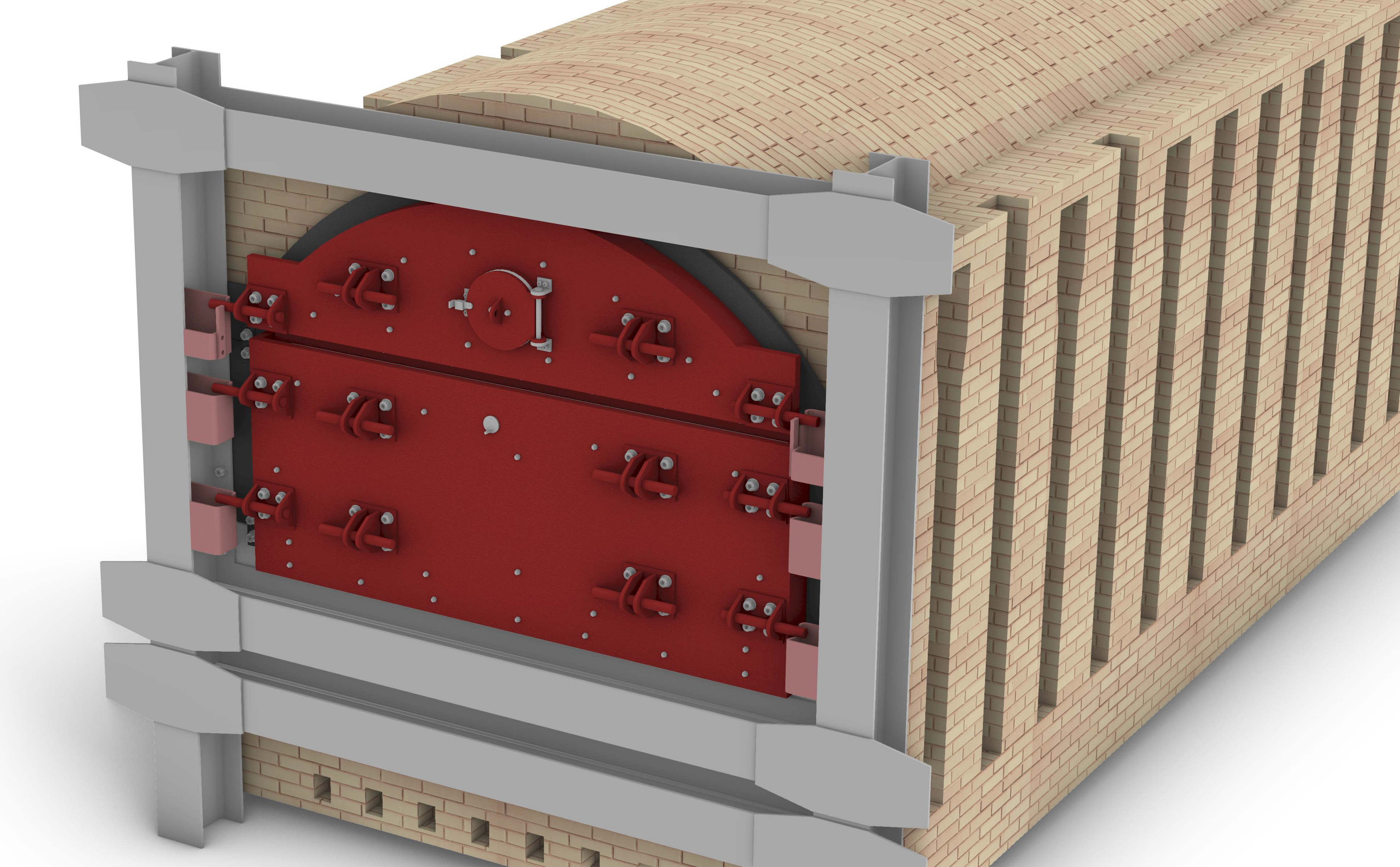

►Sensitive, quick response. The pressure could be detected in all directions.

►Safety design. After the activation, the transmitter will maintain output until reset by pressing the release button or re-start the power supply.

►Sensors are installed very close to the idler. As much as possible to eliminate the dead detecting area.

►Wire failure monitoring function. At first time detect sensor or wiring problem, ensure device working properly.

►Wire failure will activate buzzer and alarm light.

►Separate cam part, position of Alarm and Fault is adjustable according actual conditions.

►Sensor covered with additional protection, which prevents dust and conveying material from sticking.

►Water-proof, Ozone- resistant, UV-resistant, corrosion-resistant (strong acid condition will shorten the life time) suitable for extreme weather and harsh environments and high latitudes area.

|

DETECTOR |

|

Type |

NST |

|

IP Code |

IP67 |

|

Working Temp. |

-30~85°C |

|

Belt Width |

650~1800mm |

|

Chute Angle |

30°, 35°, 45° |

|

CONTROLLER |

|

Type |

RL80A |

RL80B |

RL80C |

|

Signals |

Uni-channel |

Four-channel |

Uni-channel |

|

IP Code |

IP40 |

IP67 |

|

Operating Environment |

Indoor |

Outdoor |

|

Housing Material |

ABS |

|

Working Temp. |

-20~60°C |

|

Delay Adjustable |

0~9s |

|

Power Voltage |

AC 220V 50-60HZ |

|

Number of Contacts |

1NC+1NO |

|

Capacity of Contact |

AC 125~250V 10A; DC 30V 5A; DC 125V 0.5A |

|

Maximum Cable Distance |

MAX 1km |