Conveyor emergency stop safety control belt sway switch

The Belt Sway Switch functions in detecting any deviation or sway in the conveyor belt and providing an auto-alarm and sending out signal to stop the conveyor to avoid the damage to the conveyor belt and prevent scatter of conveyed materials because of the belt distortion. The Belt Sway Switch is necessary in the safe conveying system, widely used in the belt deviation detection of the belt conveyor for coal, cement and building materials, mining, electricity, port, metallurgy and chemical industries.

Its functions are in two levels: one for auto-alarm, the other for auto-stop. During the operation of the belt conveyor, when the belt sways and touches the vertical roll, the roll turns on its axis; when the belt sways abnormally, it will squeeze the vertical roll and make it offset. When the vertical roll is at 20 slant, the first level switch function may send the alarm signal. When it continues to be at 35 slant, the second level switch function works to send the stop signal. The first level signal functions to alarm the switch to adjust deviation automatically. The second level signal functions to stop the conveyor automatically. After the fault clearing, the belt departs from the vertical roll and operate normally, the roll may reset automatically.

Belt Sway Switch is constructed with high reliability microswitches, lubricateless ball bearings, a touch roller which is titled to 75 , and other parts; its functions are designed with a large margin for sure action and long life.

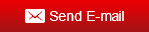

Belt Sway Switch FM2035

►Protection Grade is IP67, suitable for in most harsh environments.

►Leading technology of dual bearing structure, ensure the transmission shaft move smoothly, stably.

►Built-in two sets of micro-switches. Output Alarm and Fault signals respectively.

►Transmission shaft is made from SUS304 stainless-steel and precisely machined by lathe, grinders. Chemical alkaline or acid corrosion-resistance, moisture-free with perfect sealing.

►Roller Lever can incline to a maximum angle of 75°.

►Through the adjustment of the cam, the exact switching angle can be determined as actual application condition.

►Robust and durable.

Belt sway switch Parameters:

|

Type |

FM2035 |

|

IP Code |

IP67 |

|

Roller Operating Torque |

3.4~5.5 N·m (0.35~0.55Kgf·m) |

|

Number of Contacts |

1NO+1NC |

|

Capacity of Contacts |

AC 120V/250V 10A; DC 30V 5A. |

|

Inclination Angle of Roller Lever |

Max 75° |

|

Cable Size |

Ø6~12mm |

|

Insulation Resistance |

≥ 100M |

|

Operation Times |

>500,000 times |

|

Working Temp. |

-20~60°C |

|

Working Humidity |

≤80% |

|

Material |

SUS304 stainless-steel |

|

N.W. |

2.6kgs |

Installation:

|

1. Fix the BELT SWAY SWITCH in mounting bracket and located on both sides of conveyor belt. |

|

2. Select suitable mounting supports according to belt straight deviation, the angle is as same as belt dip angle. |

|

3. The angle of mounting support is as same as belt dip angle, and now the roller lever is vertical with belt surface |

Fittings:

|

NAME |

MODEL |

HEIGHT |

BELT WIDTH |

|

Mounting Frame (Adjustable Height) |

ZJ005-1 |

H=200mm |

Belt Width 650mm, 35° |

|

Mounting Frame (Adjustable Height) |

ZJ005-2 |

H=260mm |

Belt Width 650mm, 45°; Belt Width 800mm, 35° |

|

Mounting Frame (Adjustable Height) |

ZJ005-3 |

H=325mm |

Belt Width 800mm, 45°; Belt Width 1000mm, 35° |

|

Mounting Frame (Adjustable Height) |

ZJ005-4 |

H=425mm |

Belt Width 1000mm, 45°; Belt Width 1200mm, 35° |

|

Mounting Frame (Adjustable Height) |

ZJ005-5 |

H=525mm |

Belt Width 1200mm, 45°; Belt Width 1400mm, 35° |

|

Mounting Frame (Adjustable Height) |

ZJ005-6 |

H=625mm |

Belt Width 1400mm, 45°; Belt Width 1600mm, 35°

|

|

Mounting Frame (Adjustable Height) |

ZJ005-7 |

H=700mm |

Belt Width 1600mm, 45° |