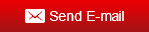

TCL Series Sedimentation Filtration Centrifuge

Description:

Sedimentation filtration centrifuge is a kind of solid-liquid separator for continuous production. Making use of differential of specific gravity and centrifugal force, it enlarges thousands of times. The solid settles down under the centrifugal force and are discharged out of the machine by special structure. The whole feeding and separation process are continuous, closed and automatic. It's widely applied to floatation of coarse coal, middling and primary slime as well as dewatering of underflow of cyclone in chemical, pharmacy, food, coal and sewage treatment industries.

Working Principle:

The centrifuge forms annular liquid layer by suspending liquid of rotary drum. Solid particles settle on the wall of drum to be dragged. Clear liquid is discharged by overflow outlet or suction tube which is called separation liquid. Then, dregs are discharged manually or mechanically. Solid particles move axially with the liquid during sedimentation process. For overfeeding, materials will float with the liquid to the flow outlet while the unsettled fine particles will be discharged from the drum and make the separation liquid turbid. Sedimentation centrifuge with high separating factor is suitable for suspending liquid of small density difference of solid-liquid, small solid particle sizes or large viscosity of liquid. To prolong the residence time of suspending liquid in the drum (such as reducing feeding volume or adopting long rotary drum) can ensure clear separation liquid.

Performance Characteristics:

1.Main spare parts like drum adopts corrosion resistant stainless steel;

2.The spiral is wear-resistant which can be welded with hard alloy protective layer or inserted with alloy corrosion coupon.

3.High draw ratio and rotary speed. Drum cone structure of multi-angles;

4.Cycloidal pin wheel, planet gear or hydraulic differential of heavy load with large transmission ratio are available; 5.Differential rotation speed and torque can be controlled by microcomputer which automatically adjusts the concentration of materials and change of flow;

6.The machine with BD plate can concentrate, dewater the primary sedimentation and active sludge of different proportion and separate materials.

Specifications:

|

Model |

Drum Diameter (mm) |

Drum Length (mm) |

Drum Rotary Speed (r/min) |

Main Power(KW) |

Application |

Capacity (t/h) |

Weight (t) |

|

TCL-0918 |

900 |

1722 |

800, 1000 |

100 |

Clean coal flotation |

10-20 |

11.34 |

|

TCL-0924 |

900 |

2320 |

800 |

115 |

Clean coal flotation |

15-25 |

11.9 |

|

TCL-1134 |

1104 |

3212 |

900,1100,1300 |

300 |

Clean coal flotation/Coal carried by popline |

40-50 |

24 |

|

TCL-1418 |

1358 |

1868 |

480,550,650 |

190 |

Clean coal flotation |

50-60 |

18 |

|

TC-0924 |

900 |

2440 |

1000 |

110 |

Tail coal flotation |

10-25 |

13 |

|

TC-1134 |

1100 |

3350 |

850 |

300 |

Tail coal flotation |

15-30 |

27 |

Notes: Handling capacity is affected by factors such as feeding material properties, particle size composition and feeding thickness.