Belt Conveyor Emergency Stop Equipment Safety Control Pull Cord Switch

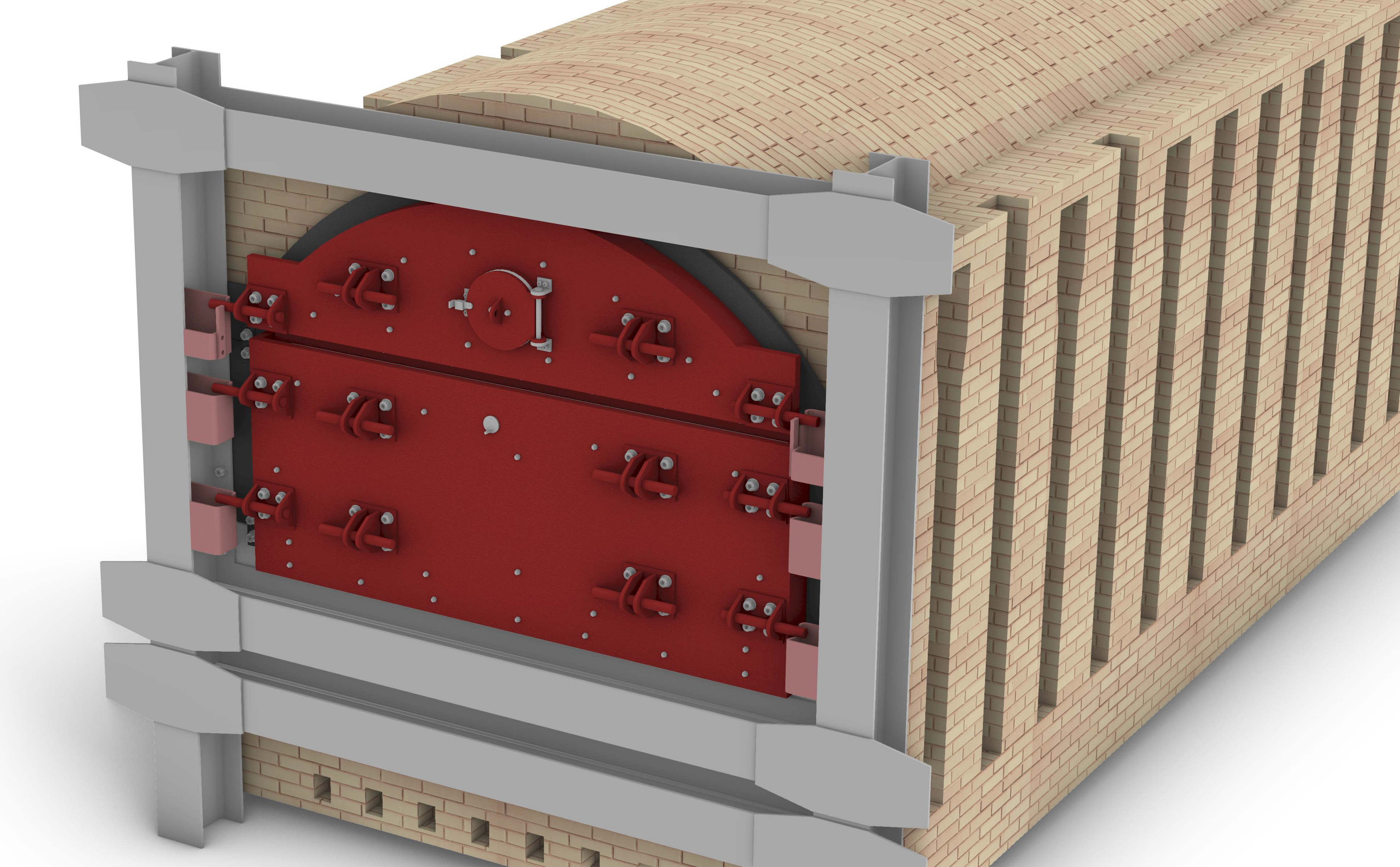

The Pull Cord Switch is installed at the side of belt conveyor and connected with cord along all long of the conveyor. When an emergency case occurs, the worker can stop the belt conveyor at any position by pulling the cord, which drives the actuating arm rotating. Thru mechanism transmission, rotatory actuating arm will finally drive cam and activate the Micro-Switches. Micro-switches will OPEN (cut off) the control circuit and stop the belt operation. When the operating lever is pulled to the angle of 30°, it would be latched. MANUAL RESET is required.

Belt Conveyor Pull Cord Switch

1 Protection Grade is IP67, suitable for in most harsh environments.

2 Leading technology of dual bearing structure, ensure the transmission shaft move smoothly, stably.

3 Built-in two sets of micro-switches. Output Alarm and Fault signals respectively.

4 Using high-strength of 12.9 grade and SUS304 fitting.

5 Transmission shaft is made from SUS304 stainless-steel and precisely machined by lathe, grinders. Chemical alkaline or acid corrosion-resistance, moisture-free with perfect sealing.

6 Separate cam part, position of Alarm and Fault is adjustable according actual conditions.

7, 5 slots of spring fixing, spring tension adjustable. Satisfy fine-tune the operating torque.

8 Special anti-corrosion requirements can be customized.

Pull Cord Switch Parameters

|

IP Code |

IP67 |

|

Operating Torque |

49±10N (5±1kgf) |

|

Number of Contacts |

1NO+1NC |

|

Capacity of Contacts |

AC 120V/230V/480V 10A; DC 30V 5A;

DC 125V 0.5A; DC 250V 0.25A |

|

Operating Angle |

20° |

|

Cable Size |

Ø6~12mm |

|

Mechanical Life |

>100,000 times |

|

Electrical Life |

>500,000 times |

|

Working Temp. |

-20~60°C |

|

Working Humidity |

≤80% |

|

Material |

SUS304 stainless-steel |

|

N.W. |

1.82kgs |

Installation:

|

1. Fix the PULL CORD SWITCH in mounting bracket. |

|

2. The distance between two switch is 30m and combined with Ø3mm plastic coated wire ropes, with moderate tightness. |

|

3. Install supporting rings in every other 2.5m to hold up wire rope, which reduces the gravity to effect the automatic reset. |

|

4. Tie the wire rope end in a tension spring (fixed in a cord clamp) and evenly strain the rope with a tightener on both sides. |

Fittings:

Plastic Coated Steel Wire Cord Tension Spring

Type: RS03/04 Type: RH003

Specification: Ø3/Ø4mm Specification: 140*20*3mm

Remark: Red Remark: Galvanized Carbon Steel/SUS304

Q’ty: 60M/Switch Q’ty: 2PCS/Switch

Cord Anchor Hook Cord Clamp

Type: TH009 Type: SK001

Specification: 185*7.2mm Specification: 4#

Remark: Galvanized Carbon Steel Remark: Galvanized Carbon Steel

Q’ty: 20PCS/Switch Q’ty: 6PCS/Switch

Mounting Bracket

Type: ZJ004

Specification: 150*210*110mm

Remark: Galvanized Carbon Steel

Q’ty: 1PC/Switch