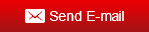

Flocculant adding and mixing system

AAP6 type flocculant adding and mixing system is a fully automatic control system that automatically prepares and doses dry powder flocculants, monitors the sludge (slime) sedimentation in the thickener, and automatically adjusts the dosage. The system includes six parts: screw feeding mechanism, air conveying device, stirring mechanism, quantitative pumping device, heating equipment and electric control system. It has the characteristics of high reliability, simple interface control, practical software functions, flexible control methods and high precision.

1, stirring mechanism 2, screw feeding mechanism

3, air conveying device 4, quantitative pumping device

5, heating equipment 6, electronic control system

Main features:

It has a high degree of automation. The system is controlled by PLC. It has an intuitive man-machine interface. The action and process parameter control of each link are automatically completed by the electronic control system, which is simple and convenient to operate. The system can not only complete the preparation and addition tasks accurately according to the set concentration and addition amount, but also display and output key process parameters such as the preparation concentration and the addition amount of the agent, so that the addition process of the agent has quantitative data and ensures the addition scientific and rational.

-

The powder is added by the screw feeding mechanism, which not only ensures the integrity of the molecular chain of the agent during the powder dosing process, but also ensures the accuracy and uniform dispersion of the feeding, and can automatically adjust the dosage according to the actual requirements.

-

In the premixer, the flocculant particles are evenly mixed with clean water, which not only avoids the formation of micelles, but also accelerates the dissolving process of the flocculant.

-

The agitator is installed at an angle of 25° to the axis of the barrel, which enhances the stirring effect.

4. The whole equipment is made of 304 stainless steel, with good corrosion resistance