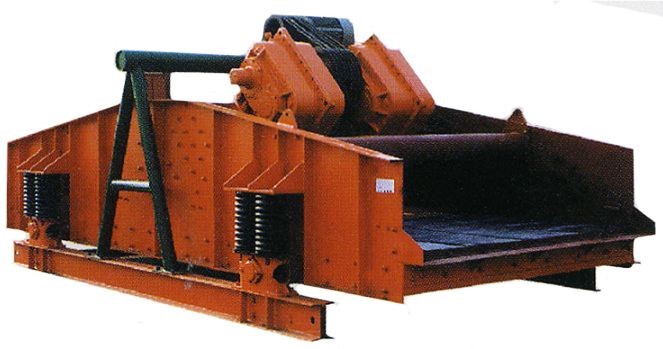

ZKX Series Horizontal Vibrating Screen

Description

ZKX Series Horizontal Vibrating Screen uses the exciter as vibration source, so that the materials are tossed up on the meshes, while moving forward. The materials are evenly discharged through the multi-layer classification meshes. Then different classified materials are divided.

Main Features:

The structure of the vibrator is box shaped with internal eccentric block, oil lubrication, and it is equipped with special bearings for vibrating machinery, which ensures high carrying capacity, long life.

It is categorized single-layer screens, double-layer screens and triple-layer screens, in total 26 models. Customized products are also available.

Specifications:

|

Model |

Mesh |

Feed size (mm) |

Capacity (t/h) |

Frequency (Hz) |

Amplitude (mm) |

Motor |

|

layer |

Area (m2) |

Opening (mm) |

material |

model |

Power (kw) |

|

ZKX936 |

1 |

3 |

0.5-13 |

①③ |

≤100 |

20-35 |

14.83 |

4-4.75 |

Y132M-4 |

7.5 |

|

2ZKX936 |

2 |

3 |

3-50 |

first layer②③

second layer ①③ |

≤300 |

20-35 |

14.83 |

4-4.75 |

Y132M-4 |

7.5 |

|

0.5-13 |

|

ZKX1236 |

1 |

4 |

0.5-13 |

①③ |

≤100 |

30-50 |

14.83 |

4-4.75 |

Y132M-4 |

7.5 |

|

2ZKX1236 |

2 |

4 |

3-50 |

first layer②③

second layer ①③ |

≤300 |

30-50 |

14.83 |

4-4.75 |

Y132M-4 |

7.5 |

|

0.5-13 |

|

ZKX1248 |

1 |

5.8 |

1.5-13 |

①③ |

≤100 |

33-55 |

14.83 |

4-4.75 |

Y132M-4 |

7.5 |

|

2ZKX1248 |

2 |

5.8 |

3-50 |

first layer②③

second layer ①③ |

≤300 |

33-55 |

14.83 |

4-4.75 |

Y160M-4 |

11 |

|

0.5-13 |

|

ZKX1536 |

1 |

5.4 |

0.5-13 |

①③ |

≤100 |

35-55 |

14.83 |

4-4.75 |

Y132M-4 |

7.5 |

|

2ZKX1536 |

2 |

5.4 |

3-50 |

first layer②③

second layer ①③ |

≤300 |

35-55 |

14.83 |

4-4.75 |

Y160M-4 |

11 |

|

0.5-13 |

|

2ZKX1542 |

2 |

6 |

3-50 |

first layer②③

second layer ①③ |

≤300 |

40-55 |

14.83 |

4-4.75 |

Y160M-4 |

11 |

|

0.5-13 |

|

ZKX1548 |

1 |

7 |

0.5-13 |

①③ |

≤100 |

42-70 |

14.83 |

4-4.75 |

Y160M-4 |

11 |

|

2ZKX1548 |

2 |

7 |

3-50 |

first layer②③

second layer ①③ |

≤300 |

42-70 |

14.83 |

4-4.75 |

Y160M-4 |

11 |

|

0.5-13 |

|

2ZKX1744 |

2 |

7.48 |

3-50 |

first layer②③

second layer ①③ |

≤250 |

38-80 |

14 |

4-4.75 |

Y180M-4 |

22 |

|

0.5-13 |

|

ZKX1836 |

1 |

6.5 |

0.5-13 |

①③ |

≤100 |

45-85 |

14.83 |

4-4.75 |

Y132M-4 |

7.5 |

|

2ZKX1836 |

2 |

6.5 |

3-50 |

first layer②③

second layer ①③ |

≤300 |

40-85 |

14.83 |

4-4.75 |

Y160M-4 |

11 |

|

0.5-13 |

|

3ZKX1836 |

3 |

6.5 |

3-50 |

first layer②③

second layer ①③ |

≤100 |

45-85 |

14.75 |

4-4.75 |

Y160L-4 |

15 |

|

0.5-13 |

|

2ZKX1842 |

2 |

7.6 |

3-50 |

first layer②③

second layer ①③ |

≤300 |

50-90 |

14.83 |

4-4.75 |

Y160M-4 |

11 |

|

0.5-13 |

|

ZKX1848 |

1 |

8.5 |

0.5-13 |

①③ |

≤100 |

60-100 |

14.83 |

4-4.75 |

Y160M-4 |

11 |

|

2ZKX1848 |

2 |

8.5 |

3-50 |

first layer②③

second layer ①③ |

≤300 |

60-100 |

14.83 |

4-4.75 |

Y160L-4 |

15 |

|

0.5-13 |

|

ZKX2148 |

1 |

10 |

0.5-13 |

①③ |

≤100 |

70-110 |

14.83 |

4-4.75 |

Y160M-4 |

11 |

|

2ZKX2148 |

2 |

10 |

3-50 |

first layer②③

second layer ①③ |

≤300 |

70-110 |

14.83 |

4-4.75 |

Y180L-4 |

22 |

|

0.5-13 |

|

ZKX2160 |

1 |

13 |

0.5-13 |

①③ |

≤100 |

70-110 |

14.83 |

4-4.75 |

Y180L-4 |

22 |

|

2ZKX2160 |

2 |

13 |

3-50 |

first layer②③

second layer ①③ |

≤300 |

90-150 |

14.83 |

4-4.75 |

Y200L-4 |

30 |

|

0.5-13 |

|

ZKX2448 |

1 |

12 |

0.5-13 |

①③ |

≤100 |

80-125 |

14.83 |

4-4.75 |

Y160L-4 |

15 |

|

2ZKX2448 |

2 |

12 |

3-50 |

first layer②③

second layer ①③ |

≤300 |

80-125 |

14.83 |

4-4.75 |

Y180L-4 |

22 |

|

0.5-13 |

|

ZKX2460 |

1 |

14 |

0.5-13 |

①③ |

≤100 |

95-172 |

14.83 |

4-4.75 |

Y180L-4 |

22 |

|

2ZKX2460 |

2 |

14 |

3-50 |

first layer②③

second layer ①③ |

≤300 |

95-170 |

14.83 |

4-4.75 |

Y200L-4 |

30 |

|

0.5-13 |

|

ZKX2470 |

1 |

16.9 |

3-50 |

①③ |

≤150 |

170 |

14.83 |

4-4.75 |

Y200L-4 |

30 |

Remarks: Different materials of screen mesh are available: ① stainless steel strip mesh, ② woven mesh, ③ polyurethane mesh