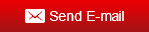

XJM Series Flotation Separator machine

Description:

This machine with single groove volume of 2.5m³~90m³, is mainly used for coal slime below 0.5mm flotation, as well as nonferrous metal, rare metal, black metal and nonmetal particle minerals. The series product has advantages of compact structure, light weight, uniform bubble distribution, large handling capacity, flexible process flow, convenient and reliable operation, etc.

Main Features:

1. Adopted impeller aspirating mechanical agitation

It is consisted of fixed part and rotary part. The impeller rotating and the stator play a role in aspirating and agitating the coal slime in the cell. The impeller is made of ductile cast iron, which improve its wear-resisting property.

2. The inflating volume can reach 1.2~1.3m3/m2. Min

3. The unit capacity can reach 0.6~1.2t/h. M3

This series of flotation separator have the features of compact structure, light weight, homogeneous air bubble distribution, great capacity, flexible technical process, convenient operation and reliable work.

Working Principle:

By the impeller rotating, the coal slurry is carried to the suction chamber through the suction bent pipe. Under the centrifugal force of the impeller, the air and coal slurry were inhaled into the impeller due to the internal negative pressure, and then were equally mixed. Effected by proper additives, the coal and agents can be separated due to their different hydrophilic nature.

Techinical Specifications:

|

Technical Specifications |

Model |

|

XJM-S4 |

XJM-S6 |

XJM-S8 |

XJM-S12 |

XJM-S14 |

XJM-S16 |

XJM-S20 |

XJM-S24 |

XJM-S28 |

XJM-S36 |

XJM-S45 |

|

Single tank volume m3 |

4 |

6 |

8 |

12 |

14 |

16 |

20 |

24 |

28 |

36 |

45 |

|

Capacity per unit |

0.6~1 |

0.6~1 |

0.6~1 |

0.6~1 |

0.6~1 |

0.6~1 |

0.6~1 |

0.6~1 |

0.6~1 |

0.6~1 |

0.6~1 |

|

(t/m3·h) |

|

Pulp handling capacity per unit (m3/m3·h) |

6~10 |

6~10 |

6~10 |

6~10 |

6~10 |

6~10 |

6~10 |

6~10 |

6~10 |

6~10 |

6~10 |

|

Aeration rate |

0.6~1.2 |

|

|

|

|

(m3/m2·min) |

|

Stirring power (kw) |

15 |

18.5 |

22 |

30 |

30 |

37 |

45 |

55 |

55 |

75 |

75 |

|

Foam scraper power (kw) |

1.5 |

1.5 |

1.5 |

1.5 |

1.5 |

2.2 |

2.2 |

4 |

4 |

4 |

4 |

|

Dimension |

Length |

3 tanks |

6785 |

7685 |

8200 |

9494 |

10200 |

10970 |

12260 |

12564 |

13313 |

14515 |

16545 |

|

(mm) |

4 tanks |

8690 |

9890 |

10555 |

12254 |

13205 |

14175 |

15715 |

16272 |

17271 |

18870 |

21555 |

|

|

5 tanks |

10595 |

12095 |

12910 |

15014 |

16210 |

17380 |

18170 |

19980 |

21229 |

23225 |

26565 |

|

Width (mm) |

2150 |

2150 |

2750 |

3120 |

3270 |

3450 |

3700 |

3950 |

4200 |

4600 |

4870 |

|

Height (mm) |

2758 |

2758 |

2956 |

3250 |

3310 |

3433 |

3503 |

3566 |

3607 |

4728 |

4805 |