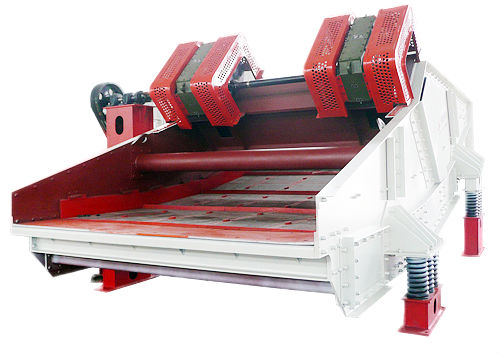

Twin screw loss in weight feeder

In the process of continuous extrusion production, various material should be added to extruder continuously synchronized. And the adding speed of these materials should depend on corresponding formula, so loss in weight feeder is necessary to control the adding speed. And one feeder control one material.

Loss-in-weight feeder is suitable for plastic granules, powder, calcium carbonate, talcum powder, resin membrane powder, flour, starch and so on. Different material use different feeders.

Characteristics of Twin screw feeder:

◆ Generous and beautiful appearance: comparing with traditional feeders, Hikmin dose more improvements on feeders’ appearance.

◆ Small in size: easy to move, more suitable for changing and improving production process.

◆ Low noise: comparing with other feeders, noise of Hikmin feeders is up to perfect.

◆ Easy to clean and maintain: it’s easy to maintain in operation, meanwhile, very short maintenance time. Especially the control system, adopting the leading software and hardware, are nearly free-maintenance and long-service life.

◆ High feeding accuracy: Hikmin adds self-detection function when designing its feeders for more accuracy, it allows to detect attritions of parts and frequency variation timely, then revise them. So the feeder will not affect the feeding precision because a little change of the machine.

Structure:

Parameters:

|

Type |

Screw

specification |

Capacity

(L/H) |

Driving power

(kw) |

Hopper (L)

(optional) |

Feeding

accuracy |

|

MF-TS28 |

28 |

10-200 |

1.1 |

40-80 |

±0.2% |

|

MF-TS38 |

38 |

30-400 |

1.1 |

40-100 |

±0.2% |

|

MF-TS46 |

46 |

50-800 |

1.5 |

40-120 |

±0.2% |

|

MF-TS64 |

64 |

60-1200 |

2.2 |

40-150 |

±0.2% |

Notes: The feeding capacity and accuracy will be affected by different materials.