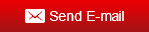

Coking Coal Briquette Making Machine

Coal Briquette Machine is mainly used for pressing materials with low water content such as all kinds of coal briquette, ore powder and refractory. Hikmin ball press machine is a new type of briquette machine with high efficiency, energy conservancy and environment protection. Materials after being briquetted by coal briquetting machine is smaller, energy saving, environmental friendly, easy to transport and improved in wastes recycling rate, which make it have good economic and social benefit.

Application of Coal Briquette Machine

Coal briquetting machine can be used to press all kinds of powdery materials like coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, gypsum, tailings, sludge, kaolin, clay, activated carbon, coke and waste residue in refractory, power plant, metallurgy, chemistry, energy, transportation, heating and other industries.

Structural Features of Coal Briquette Machine

The performance of the coal briquetting machine is mainly determined by the roller skin of the main engine. This type of coal briquette machine is casted with 65 manganese, and with special heat treatment, its hardness can reach over 58 degree. The roller skin adopts composite assembly, so that it can be changed when abraded. This briquette machine has a shock absorber which can better protect the equipment from the impact of hard materials. The briquette machine is designed with ball bowl adjustable device to make sure the ball bowls of the two rollers are always in the adjustable range.

Working Principle of Coal Briquette Machine

Host gets power from the electromagnetic adjustable speed motor, and drives the driving shaft rotating by a reducer. The driving shaft and driven shaft keep synchronization operation. After the pressed material enter the feeding mouth, it is pressed into ball under great pressure. At the back of ball press machine, the hydraulic devices are installed, and it can protect the ball press machine from damaging when super hard material enters it.

Process FLow of Coal Briquetting Plant

1. Get raw material prepared: sieving, pulverizing the charcoal lumps/chunks or coal mateirals into fine powder.

2. Get appropriate binder.

3. Mixing process: mixing coal / charcoal powder with binders and some other additives if needed.

4. Briquetting process/Extruding process: briquetting/extruding mixed charcoal powder into specific shape with charcoal making machine.

5. Drying process: sun drying or automated tunnel type continuous drying

6. Packing process: carton packing, gunny packing, paper packing.

Technical Data of Coal Briquette Machine

|

Performance |

HM-360 |

HM-400 |

HM-500 |

HM-650 |

|

Output |

hour (t/h) |

4 |

8 |

11 |

18 |

|

Annual output (million t/y) |

1 |

2 |

3 |

5 |

|

Roller breadth (mm) |

250 |

280 |

300 |

336 |

|

Roller diameter (mm) |

360 |

400 |

500 |

650 |

|

Power(kw) |

7.5 |

11-15 |

18.5-22 |

20-30 |

|

Speed of mainshaft (r/min) |

18 |

15 |

13 |

13 |

|

Reducer |

ZQ350 |

ZQ400 |

ZQ500 |

ZQ650 |

|

ZQ400 |

ZQ500 |

ZQ650 |

ZQ750 |

|

Pressure form |

Oblique iron constant pressure |

Oblique iron constant pressure |

Oblique iron constant pressure |

Oblique iron constant pressure |

|

Axle bed pull rod |

Axle bed pull rod |

Hydraulic type |

Hydraulic type |

|

|

|

Interchangeable of hydraulic and constant pressure |

Interchangeable of hydraulic and constant pressure |

|

Roller texture |

65Mn |

65Mn |

65Mn |

65Mn |

|

|

|

9cr2Mn |

9cr2Mn |

|

Alloy steel |

Alloy steel |

Alloy steel |

Alloy steel |

|

Structural style |

Double-roller&single pressure type |

Double-roller&single pressure type |

Double-roller&single pressure type |

Double-roller&single pressure type |

|

Four-roller&dual pressure type |

Four-roller&dual pressure type |

Four-roller&dual pressure type |

Four-roller&dual pressure type |

|

Mainshaft bearing |

319*4 |

319*4 |

2097724*4 |

2097724*4 |

|

Principal axis |

Ø95mm |

Ø110mm |

Ø135mm |

Ø165mm |

|

45# steel |

45# steel |

Forge piece |

Forge piece |

|

Spherical size |

User defined |

User defined |

User defined |

User defined |

|

Performance |

HM-750 |

HM-850 |

HM-1250 |

Instruction |

|

Output |

hour (t/h) |

25 |

35 |

70 |

|

|

Annual output (million t/y) |

7 |

10 |

20 |

|

Roller breadth (mm) |

400 |

500 |

650 |

65Mn |

|

Roller diameter (mm) |

750 |

850 |

1250 |

|

|

Power(kw) |

45 |

75 |

130 |

According to the materials |

|

Speed of mainshaft (r/min) |

13 |

10 |

10 |

|

|

Reducer |

ZQ750 |

ZQ850 |

ZQ1250 |

Standard configuration |

|

|

|

|

Reinforced configuration |

|

Pressure form |

Oblique iron constant pressure |

Oblique iron constant pressure |

Oblique iron constant pressure |

Optional |

|

Hydraulic type |

Hydraulic type |

Hydraulic type |

|

Interchangeable of hydraulic and constant pressure |

Interchangeable of hydraulic and constant pressure |

Interchangeable of hydraulic and constant pressure |

|

Roller texture |

65Mn |

65Mn |

65Mn |

Casting |

Either type |

|

9cr2Mn |

9cr2Mn |

9cr2Mn |

Forging |

|

Alloy steel |

Alloy steel |

Alloy steel |

Pressure casting

|

|

Structural style |

Double-roller&single pressure type |

Double-roller&single pressure type |

Double-roller&single pressure type |

Either type |

|

Four-roller&dual pressure type |

Four-roller&dual pressure type |

Four-roller&dual pressure type |

|

Mainshaft bearing |

2097724*4 |

2097724*4 |

2097724*4 |

|

|

Principal axis |

Ø165mm |

Ø180mm |

Ø225mm |

|

|

Forge piece |

Forge piece |

Forge piece |

Hardening and tempering |

|

Spherical size |

User defined |

User defined |

User defined |

Generally choose 30-60mm |