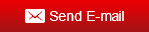

Hydraulic High Pressure Ball Press Machine

Hydraulic high pressure ball press machine can compress and shape all kinds of mineral powder, metal powder, coal powder and other materials. Because of the mandatory extrusion of twin-roller, the processed product has these advantages, such as high density, large strength, high hardness and so on. The roller of the machine is made by 650 mm hard material, and its wear resistance is very good, which can greatly improve the service life of the roller.

Application of High Pressure Ball Press Machine

Application of High Pressure Ball Press Machine

High pressure ball press machine or high pressure ball press machine is mainly used to make the coal powder, iron powder, coke, aluminum powder, scrap iron, sinter, toner, carbon dust, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke breeze and other powders and wastes, which is widely used in refractory, power plants, metallurgy, chemical industry, energy, transport, heating and other industries. The molding materials after the processing of high pressure briquetting machine are energy saving and easy to transport, improving the utilization rate of waste materials and having good economic and social benefits.

Structure of High Pressure Ball Press Machine

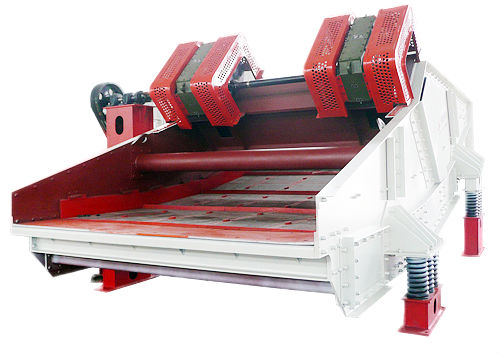

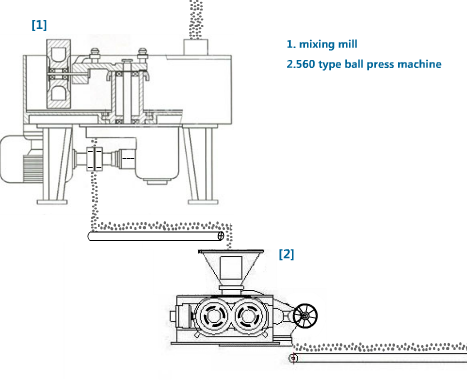

1) Feeding device: it is mainly used to achieve constant feeding to ensure that materials enter the gap between the rollers evenly.

2) Transmission parts: the main transmission system includes motor - triangle belts---reducer --- --open gear ----rollers.

3) Molding part: it mainly refers to the host and the core part is the roller.

Working Process of High Pressure Ball Press Machine

This series of high pressure ball press machine passes power to the two rollers through the reducer at the same time, and makes the two rollers rotate in the opposite direction. In the process of the two rollers rotating, the material naturally goes into the ball mold on the roller.

As the rotating of rollers, the pressure that material bears changes from small to big, and when the material rotates to the contact point of the two rollers' lines, the pressure that material bears has reached the peak. Under the great pressure of lines, material turns from powdery to finished product ball.

Technical Data of High Pressure Ball Press Machine

|

Product model |

Diameter of roller sheet (mm) |

Designed output (t/h) |

Motor power (kw) |

|

290 type |

290 |

1-3 |

5.5 |

|

360 type |

360 |

4-6 |

7.5 |

|

430 type |

430 |

6-8 |

15 |

|

500 type |

500 |

8-10 |

18 |

|

650 type |

650 |

10-15 |

25 |

|

800 type |

850 |

15-20 |

30 |

|

1000 type |

1000 |

22-30 |

45 |