Today is the first working day after new year holiday, but also it's a busy day. Because we're working on delivering the flotation cell machine to a customer in Russia. It will be used in their coal preparation plant for coal slime separation.

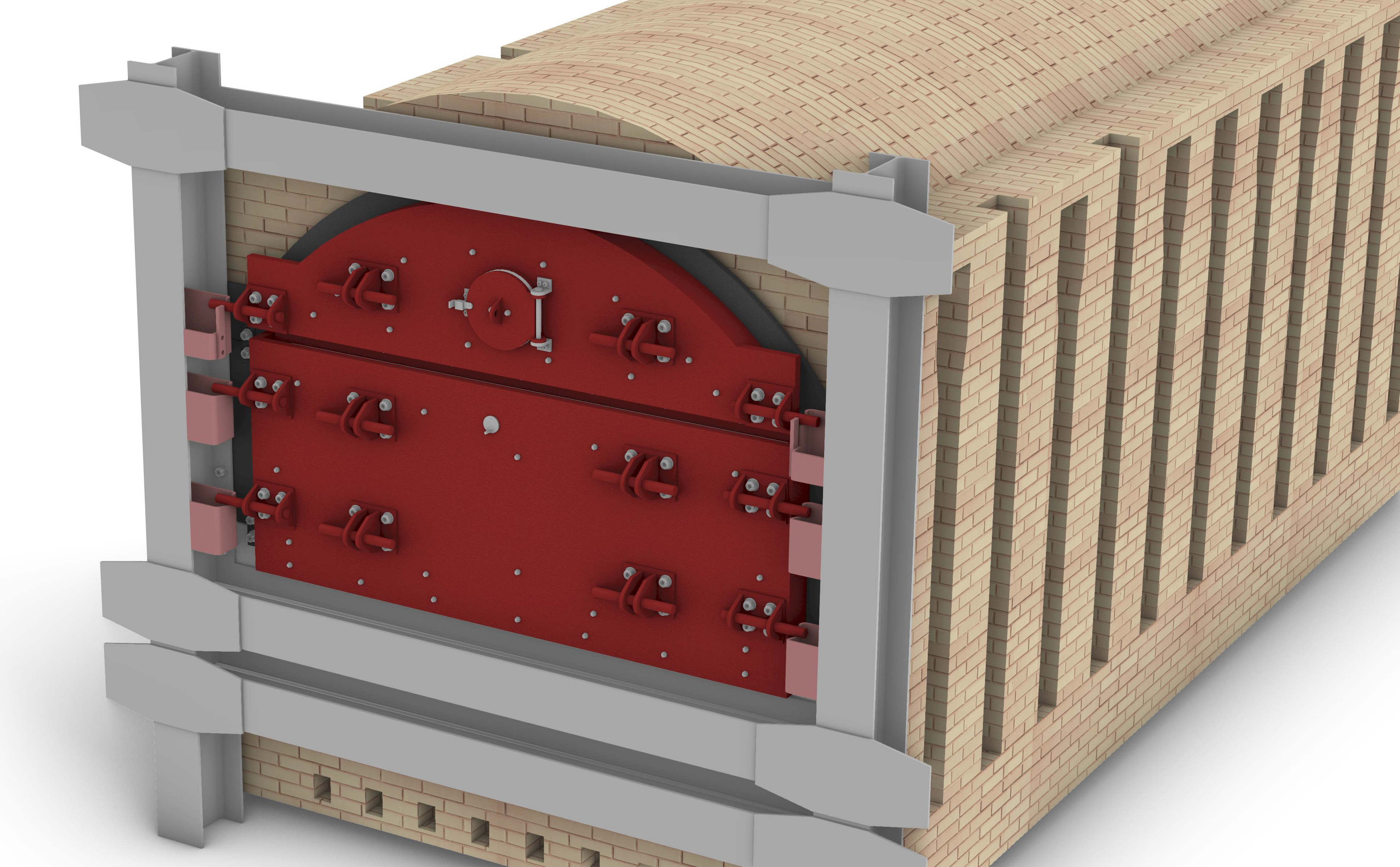

Flotation Separator Machine Working Principle:

By the impeller rotating, the coal slurry is carried to the suction chamber through the suction bent pipe. Under the centrifugal force of the impeller, the air and coal slurry were inhaled into the impeller due to the internal negative pressure, and then were equally mixed. Effected by proper additives, the coal and agents can be separated due to their different hydrophilic nature.

Main Features of Flotation Machine:

1. Adopted impeller aspirating mechanical agitation

It is consisted of fixed part and rotary part. The impeller rotating and the stator play a role in aspirating and agitating the coal slime in the cell. The impeller is made of ductile cast iron, which improve its wear-resisting property.

2. The inflating volume can reach 1.2~1.3m3/m2. Min

3. The unit capacity can reach 0.6~1.2t/h. M3

This series of flotation separator have the features of compact structure, light weight, homogeneous air bubble distribution, great capacity, flexible technical process, convenient operation and reliable work.